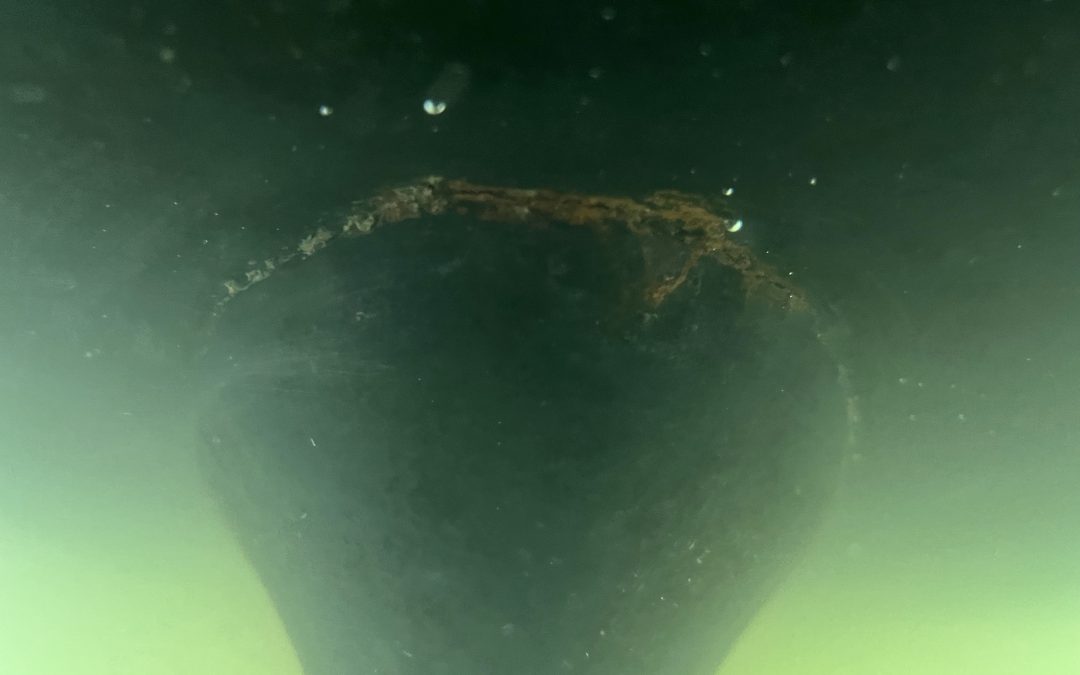

First, let’s talk about the problem. Anodes are an essential component of any marine propulsion system. They help to protect the propeller and drivetrain from corrosion by sacrificing themselves to the elements. But here’s the thing – they’re not meant to be spinning at high speeds. In fact, they’re really only designed to stay in place when the propeller is stationary.

So, when you install an anode on the end of a fast-spinning propeller, it’s only a matter of time before it falls off. And trust me, it’s not a pretty sight. The anode goes flying off into the water, leaving you with a propeller that’s no longer protected. Plus, if you’re not careful, the anode can actually cause damage to your boat or other objects in the water.

But there is a solution to this problem. It’s called the “lock washer stack.” It’s a simple trick that involves installing a stack of lock washers along with the bolt that secures the anode. The stack of 4 or 5 lock washers acts like a spring, helping to keep the anode in place even when it’s spinning at high speeds.

Here’s how you do it: First, make sure you have a good-quality lock washer that’s made from a corrosion-resistant material. 316 stainless steel is a good choice. Then, stack up 4 or 5 of these washers on top of each other and place them on the bolt before you install the anode. The washers should fit snugly against the anode, helping to keep it in place.

Finally, install the anode and bolt as you normally would, making sure to tighten everything down nice and snug. The lock washer stack should help to keep the anode in place far longer than it would otherwise stay there, reducing the risk of it falling off and causing problems.

So, there you have it – the “lock washer stack” trick for keeping anodes in place on a spinning propeller. It’s a simple solution that can save you a lot of headaches and ensure that your propeller is always protected from corrosion.

Keywords: anode, propeller, marine propulsion system, corrosion, lock washer stack, bolt, 316 stainless steel, corrosion-resistant material

Related Articles

Bottom Paint Guide

In 10 years of tracking bottom paint performance, I’ve noticed a variety of results – good and bad – in the performance of bottom paint.

Anode Issues

Anode Fasteners Falling Out Anodes lose material...

How to properly install anodes

If you are tired of replacing your anodes every...

Rusting Keel Fins

Beneteau keel fins (a very common brand of...

Propspeed not sticking to previously corroded metals

Whenever a propeller has previously suffered...

Is my boat in a hot harbor?

The problem of "hot harbors:" There are marinas...

Ask Lowell

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220