If you are tired of replacing your anodes every few months because they just can’t seem to stay put or aren’t working, I’ve got a few tips that can help ensure your anodes are doing their job and protecting your propeller and other underwater gear:

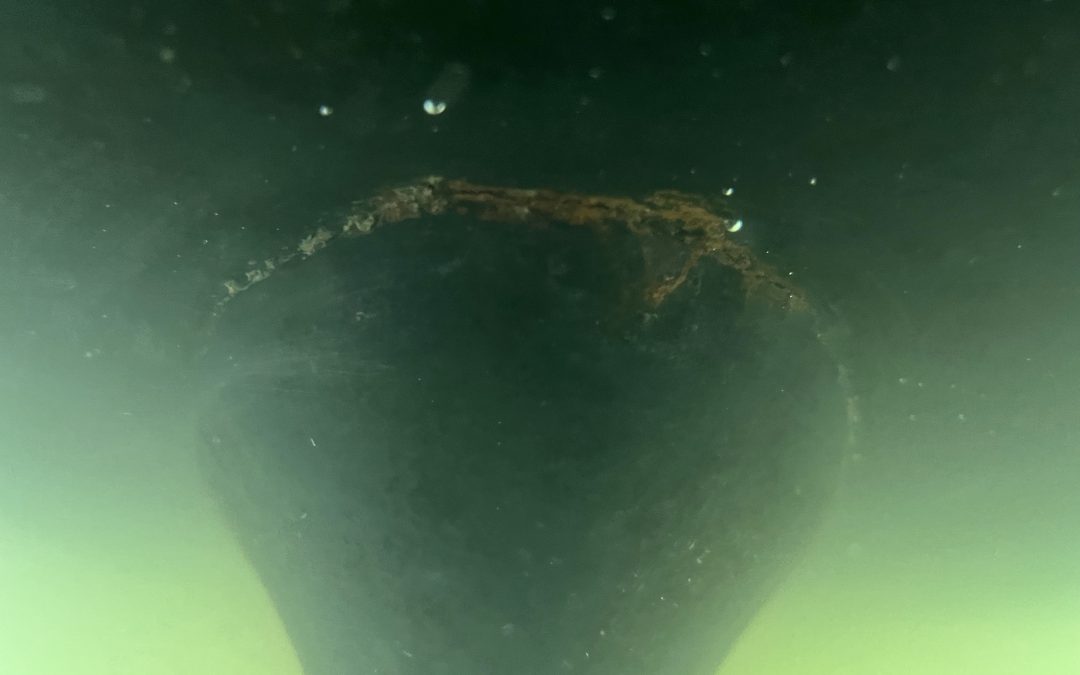

First, it’s important to make sure you’re using the right kind of anode for the job. Zinc, aluminum, and magnesium are all good options, but you’ll want to choose the one that best fits your needs. Once you’ve selected your anode, it’s time to prep the mating surface. This is where the anode will be attached to the prop or shaft, and it’s crucial to make sure it’s clean and free of oxidation.

To do this, you can use a wire wheel or 400 grit wet sandpaper to de-oxidize the surface. Just make sure not to overdo it – you want to remove enough oxidation to get back to bright metal, but not so much that you damage the surface. Once you’ve cleaned the mating surface, you’ll want to do the same for the prop shaft, strut, trim tabs, rudder, or other surface where the anode will be installed.

Once everything is clean and bright, it’s time to install the anode. Make sure to torque it down nice and snug, and then give it a light tap with a hammer to seat it properly. This tap is not a hard hit, it’s just enough to make sure the anode is properly seated. Then, re-torque it once again to ensure a secure fit.

One of the best things you can do to ensure your anode stays put is to apply a liberal coating of Tef-Gel to the entire bolt that passes through the anode, as well as to the anode surfaces where the bolt passes through and where it comes into direct contact with the anode. If your anode has a recessed removable nut, be sure to coat that as well. The use of an insulating compound like Tef-Gel creates a spot where the stainless bolt or machine screw will be galvanically isolated from the anodic metal, which can help improve the anode’s performance and longevity.

Alternatively, some people prefer to use nail polish to coat the stainless machine screw and anode screw mating surfaces. While Tef-Gel tends to perform better in my experience, nail polish is certainly better than nothing at all.

Remember, a bit of time spent preparing and installing your anodes can go a long way toward ensuring better anodic protection, more even wear, and longer anode longevity. When you’re spending $3000-$6000 on a feathering propeller, you don’t want your vessel coming out of the water looking like it’s been through a war zone. Take a little extra time during the prep and installation process to give your anodes the best chance of protecting your gear. Trust me, it’ll be worth it in the long run!

Keywords: anode installation, galvanic cell, mating surface, anode maintenance, anode cleaning, propeller corrosion, zinc anode, aluminum anode, magnesium anode ,anode protection, anode effectiveness , anode installation tips, cleaning mating surface, de-oxidizing surface, torque anode, seat anode, anode material selection, hydrocarbons, anode installation process, anode installation prep work

Related Articles

How to epoxy barrier coat lead, cast iron and other metals

When it comes to maintaining the longevity of...

Paint Haloing

If you're a boat owner, you know how important...

Rusting Keel Fins

Beneteau keel fins (a very common brand of...

Ask Lowell

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220