If you have been grappling with any of the following questions, this article is for you:

- Why did my friend’s bottom paint last 3 years and mine only lasted 1 or 2 years?

- Why is my hull getting so fouled? I just had the hull cleaned a month ago!

- Why does my waterline look like a grassy lawn when my paint is only a year old?

- Why can’t I find a diver who wants to clean my hull?

- My diver said my bottom paint has failed, but the boatyard said it looks fine?

- I am happy paying for a professional bottom paint job, but how do I know it’s good?

- One coat or two?

Table of Contents

Bottom Paint Quality Over Recent Years

Timeline of a Good Bottom Paint Job

Timeline of a Bad Bottom Paint Job

Improving the Chances for a Good Bottom Paint Job

Common Issues with Bottom Paint Jobs

How to Assess a Bottom Paint Job for Long-Lasting Performance

Miscellaneous Paint-related Products

Additional links and resources

In 10 years of tracking bottom paint performance, I’ve noticed a variety of results – good and bad – in the performance of bottom paint. I’ve wondered why one paint job gives years of steady performance, while another bottom paint job underperforms from the beginning. By looking at my records of bottom paint performance of 500+ boats in the San Francisco Bay, observing boat bottoms in my day to day job as well as painting a few bottoms myself, I have gathered these observations in hopes that other boat owners will find them interesting and helpful.

Disclaimer: I convey these ideas from a narrow perspective: a hull diver who has kept track of bottom paint performance over 10 years and on countless boats. I am still learning. These opinions should be taken along with other sources of information including the reader’s own experience. I encourage the reader to form their own conclusions.

Bottom Paint Quality Over Recent Years

Changes to paint formulas worldwide since 2020 have led to less desirable bottom paint outcomes. Everyone – paint companies, boatyards, boat owners – is adapting to a less powerful paint formula. Few, if any, experts seem to have a handle on why so many paint jobs are failing prematurely – and more importantly, what can be done about it. We know that hard bottom paints such as Pettit Trinidad, Z-Spar “The Protector,” Interlux Ultra, Interlux Micron Extra, previously relied on two biocides: copper and the anti-slime and anti-grass chemical irgarol, labeled as “Biolux” and “SR” on bottom paint.

Since 2020, the new paint formulas no longer have this secondary biocide, irgarol, to boost effectiveness. Our favorite hard bottom paint now relies on copper only, which is not enough to inhibit certain organisms. Adding to the confusion, the new formulas retained their original names and labels and have dropped only minor details from the labels. For example, Pettit Trinidad SR (Slime Resistant) became “Pettit Trinidad” – no more Slime Resistance, but it has the same legendary Trinidad name, leading to false confidence and loyalty towards the product. In the San Francisco Bay, this new copper-only generation of paint is prone to severe grass growth near the waterline and severe black embedded mold growth below the waterline. This growth used to show up only after the bottom paint was several years old or on inferior paints that were low in antifouling properties (especially those that were copper-only single biocide). Heavy grass and stubborn algae now shows up within 6 months on some boats, even when using the most expensive antifouling products. Below are a few resources regarding this topic:

Scientific article: “Antifouling efficacy of coatings is site-dependent. Marine fouling [is] affected by the binder/biocide pair”

KKMI’s 2020 article on the irgarol ban and what it could mean for bottom paint. “Unfortunately, we may find that bottom paints are not going to last as long”

Practical Sailor article on irgarol ban

Scientific data on irgarol:

https://www.sciencedirect.com/topics/chemistry/irgarol-1051

https://apps.ecology.wa.gov/publications/documents/1904020.pdf

The change in paint formula is not the only cause of unsatisfactory bottom paint jobs. Paint job performance changes from boatyard to boatyard and from customer to customer, for better and for worse. I believe there are important lessons from the best-performing bottom paint jobs that can be replicated on our own boats, no matter what kind of bottom paint we use.

My estimate is that over the past 2 years, about 50% of the newly-painted boats I cleaned received a paint job that underperformed in some significant way. Below is everything I have learned about bottom paint, including a timeline of bottom paint year after year, case studies on the best and worst bottom paint jobs I’ve observed, followed by a list of common paint problems and how I think these problems can be prevented.

Timeline of a Good Bottom Paint Job

To start, what does a good paint job mean? What is realistic paint performance? From the diver’s perspective, here is the typical timeline of a good bottom paint job:

- Year 1:

The bottom paint stays in brand new condition for at least one year. It needs periodic gentle cleanings for racing boats or for peace of mind to make sure all is well on the bottom. In the winter months, the boat may need a cleaning or two for maintenance, depending on the location. In the harshest locations or in the middle of summer, the bottom does need a cleaning within 2 to 3 months of splashing. In the lightest-growth locations (brackish water, stagnant water in estuary/basin/channel, covered/shaded slips) and/or when splashing brand new paint during the winter, the bottom can go 6 months before it needs a scrub. The paint sheds away marine growth when under sail, is extremely easy to clean by hand, and very little heavy algae appears anywhere on the hull.

- Year 2:

After a full year in the water, the paint now needs regular cleanings to get the same results as the 1st year. It needs cleaning every 2 weeks to 6 months depending on the local fouling conditions. The paint is still easily wiped clean and might even partially self-clean while underway. Some light grass along the waterline needs to be gently scrubbed away. A few thin spots where the paint is thin or under-applied are now suffering from slightly heavier growth. Note: The 2 year mark is where I have seen hundreds of paint failures due to under-painting, missed spots, less than 2 coats of paint, etc. The bottom paint will certainly not last over 2 years if there are significant areas of thin paint, or if the paint is mechanically failing – wearing away, peeling, chipping, etc. – in any significant way.

- Year 3:

After two full years in the water, most paint jobs are noticeably depleted; grass at the waterline, rudder and bow. Shellfish growth on the bottom of the keel, paint chipping away from bronze hardware. Hull chines or edges on the keel/rudder are now worn to bare gelcoat. Even on the very best bottom paint jobs, 2+ years will reveal the weakest spots. The paint is worn by repeated scrubbings, plus natural wear and tear. Any thin spots in the paint are now becoming full-blown bare spots showing gelcoat on the hull. At this point there may be some stubborn black algae embedded in the paint, and it is best to leave this in place rather than fighting it and losing more paint to aggressive scrubbing. Only the best bottom paint job will survive into its third year.

- Year 4:

After 3 full years in the water, my estimate is that less than 5% of bottom paint jobs are still performing well. This was true even before 2020 when we had access to more powerful antifouling paint. Old paint gets harder to scrub clean; whether it can be managed depends on the local fouling conditions. At this stage the paint is failing due to 1) mechanical reasons (thin/worn paint areas, paint that is flaking off at the waterline due to repeated cycles of sunlight/oxygen) and/or 2) chemical reasons (eventually the paint is simply at the end of its built-in life cycle). Important to note that most of the time, the paint fails due to mechanical reasons before the paint is chemically depleted. In other words, most of the time it is not your paint that is due for haul-out, it is your paint job. Understanding the modes of mechanical and chemical success/failure is the key to applying a long-lasting, high-performing paint job. This understanding elevates painting the bottom of a boat to a science, making the entire bottom paint job perform as a system. Not respecting the marine fouling environment, the mechanics of the paint system and/or the paint formula equals a recipe for failure.

- Year 5:

I have never seen a bottom paint lasting over 4 years, outside of one Express 34 from Richmond Yacht Club that spent every summer from June to October in the freshwater Delta, extending the life of their paint over 6 years. Cruising sailors sometimes claim their paint lasts 4+ years in salt water; these claims are not supported by an understanding of the differences between good and bad performance, and are usually accompanied by a denial of reality and low expectations of the bottom paint, which is not helpful for the typical boat owner.

Timeline of a Bad Bottom Paint Job

What does a diver mean when they talk about paint failure? This is the view from my perspective:

- Year 1:

I usually clean the bottom 2 to 3 months after the new bottom paint is splashed. The best bottom paint jobs will barely have any marine growth at this stage. But we’re looking at bad bottom paint jobs here! At 2 to 3 months old, a bad bottom paint job will have areas of excessively heavy growth; while wiping down the hull, I suddenly hit a patch of stubborn algae and say to myself, “uh oh, this spot is going to be a nightmare in a year or two.” A bad paint job might start with heavy pitting, orange peel, non-skid texture, or unsanded paint chips. These textures all make it harder to clean the bottom. The hull might have thinner paint on the jackstand squares or along the bottom of the keel. When any bottom paint is 3 months old, these problem areas are really not a big deal – but they foretell the failure of the paint. At this stage, the problems are manageable but concerning. I keep detailed records of the paint performance and try to prepare the boat owner for the inevitable.

- Year 2:

After 12 months, a bad bottom paint job will usually show heavy grass growth at the waterline. Below the waterline, some areas are now difficult or impossible to scrub clean. Black embedded algae can look like a speckling of black dots, or it can be a waxy impenetrable film over large areas of underperforming paint. This black algae is not easy to remove, and removing it comes at the cost of scrubbing away precious bottom paint. Depending on the local fouling conditions and how bad the bottom paint is, it might be time to haul and paint after 12 months. Needless to say, this news comes as a surprise to owners who expected 2+ years from their paint job. If the boat owner has a great relationship with their boatyard, sometimes the paint gets fixed or replaced at a discounted rate, but this is unfortunately very rare. I do my best to communicate with clients that the boat will need a different hull cleaning program at this stage. However, because of the owner’s disappointment, the expense of a new bottom paint job, or lack of communication by either the hull diver or the owner, a bad bottom paint job often falls into neglect at this stage.

It sounds easy to decide that the boat needs new bottom paint, or a new hull cleaning program, or a higher hull cleaning rate. In the imperfect real world, countless otherwise well-maintained boats are chronically fouled with heavy marine growth, black embedded algae, and other signs of neglect. Why is this? First, bottom paint failure is a lot more common than many people realize. Second, divers do not want to laboriously scrub bad bottom paint; they have easier boats waiting for them elsewhere. The diver might be hesitant to negotiate a higher rate with their client, as it can be tricky to explain that a bad bottom paint is 10x harder to clean than good paint. It takes effort and organization for a diver to keep track of which boats are falling into bottom paint failure, so some boats might get totally forgotten by a busy dive service.

- Year 3:

After a while with bad bottom paint, the best outcome is when the boat owner is aware the paint has failed and they have a plan to manage it with the help of their diver and boatyard. I have had a number of cherished customers who have ridden out their bad bottom paint job by attacking the situation with monthly or bi-weekly hull cleanings – knowing that the cleaning is not guaranteed to win races, but that it’s a reasonable compromise for the time being. This nursing-along can go anywhere from 6 to 24 months, depending on the local fouling conditions and the viability of the bottom paint.

A less pleasant outcome I have seen countless times is when the bottom paint has gone bad but the owner is not aware of the situation. The diver may keep cleaning the boat on a regular schedule as if it were in good condition, spending an allotted fixed time slot for a given boat, without putting in the extra work to clean the worsening bottom. This is when you see divers clean to 1 ft. below the waterline but leave the rest of the hull dirty. The owner is often none the wiser. Sooner or later, the owner realizes all is not well. The owner, if not well-versed in this industry, might burn through a few divers who may or may not have provided a thorough service or communicated about the issue. The bottom of the boat now looks like a reef and there could be corrosion issues. This is not where anyone wants to end up, but too many people end up here due to misunderstanding the unspoken secrets of working with divers and boatyards.

Case Studies

A handful of results over the past years. How they were painted, what was learned from each.

Stewball, Express 37, Richmond Yacht Club.

Paint type: Blue Pettit Trinidad Pro bottom paint containing irgarol (applied circa 2015).

This was by far the longest lasting bottom paint job I have ever seen. I was fortunate to get the whole story from the owner, Bob. The bottom was painted at the San Rafael boatyard while Stewball was en route home from the Delta. Bob requested a sprayed bottom paint job at San Rafael, but the boatyard ended up roller-applying the paint and then burnishing the paint smooth. Due to disagreement about the sprayed vs. rolled paint and another mishap during the burnishing where some areas did not turn out smooth enough, the boatyard applied 2 extra coats of paint at their own expense – arriving at 4 total coats of paint. According to Bob, there were around 5 gallons of paint applied to the hull. We wondered how the boat would race with so much paint weight on the hull! The paint was so thick that when it was splashed, the lifting straps smudged the still-tacky paint, creating smudged ridges of bottom paint over ¼” thick, similar to the texture of dried mud. The smudged lifting strap areas were left in place over a year until Bob had these areas faired and touched up with new paint for the Big Boat Series. Over four years total, I cleaned this hull on a monthly schedule. The boat won many races despite the extra paint weight. The performance of the paint was truly hard to believe. It was in brand-new condition for two solid years, and then it finally started behaving more like normal bottom paint. After 4 years, there were certain areas on the rudder and keel that were becoming too hard for me to clean, so I gave Bob the heads up that this bottom paint was finally done.

In my opinion, the variable factor in why this paint lasted so much longer than expected was that there was a LOT of paint on the hull. The paint had everything it physically needed to allow its built-in formulation to play out perfectly, delivering every last bit of its potential. I don’t have an opinion about the San Rafael boatyard. In fact, it surprises me that this less prestigious boatyard is still the “best” for this one exceptional case.

Constanza, Westsail 32, Berkeley Marina.

Paint type: Z-Spar “The Protector” bottom paint containing irgarol (applied early 2019)

This boat belongs to Bob K, an award-winning boat restoration expert. I saw Bob in person applying his Z-Spar “The Protector” in the Berkeley Marine Center boatyard. I cleaned the bottom every 2 to 4 months for over 3.5 years. After 4 years, the paint is still going strong although it’s now beginning to fail in some places. It will be almost 5 years old by the time the boat is due for haul-out. The incredible paint performance has been corroborated by another independent hull diver who cleaned this boat and told me that some areas of the hull seem to have brand new paint on them. Bob reported 3 coats of Z-Spar “The Protector” paint were rolled on. The rolled paint is expertly applied and is smooth, which is important because a smooth texture is easier to fully clean in one or two wipes, as opposed to a rough rolled texture which must be scrubbed with more pressure to remove the growth in the valleys of the paint. In my opinion the paint has lasted so long because of good attention to detail, consistent paint film thickness, and a healthy 3 coats of paint. Here is a video of a quarterly, routine hull cleaning on Constanza: 3 year old hard bottom paint containing irgarol. Note in the video that some areas on the hull are easily wiped clean, while some areas are affected by black embedded mold growth after 3 years.

Syrinx, Lyle Hess Cutter 30, Berkeley Marina.

Paint type: Seahawk Sharkskin copper-only bottom paint (applied 2014)

This is my own boat. The boat came to me painted in Seahawk Sharkskin bottom paint applied by the previous owner. I had to clean the bottom every two weeks because the paint was bad and I couldn’t afford the haul-out right away. So, I got to observe this paint as it wore down. My observation was that the areas of thicker paint retained their antifouling properties much longer than those areas that were painted with less paint to begin with. The performance discrepancy only grew wider as the paint aged. The areas of thick paint worked like magic well into the 3 year zone, while most of the paint was failing miserably (this equates to something like a 10x difference in the scrubbing effort between excellent, easy-wipe antifouling and depleted paint fouled by unbelievably stubborn grass and algae). And Seahawk Sharkskin was a low-priced, copper-only bottom paint that I despised, causing a years-long debate between myself and the boatyard where Seahawk Sharkskin was their standard paint. But I had to admit that the more heavily-applied areas of the Sharkskin paint were performing well even at the 3 year mark. This phenomenon is similar to my observation on hundreds of other boats: As we know the standard bottom paint job consists of 2 coats. Many boatyards wisely apply a third coat to the rudder and the waterline. I have observed more times than I can count that the third coat on the rudder puts the rudder paint in a different world of performance and longevity, compared to the 2 coats on the hull. The 2-coat areas on the hull get old and difficult to clean within about 2 years. At that point, the rudders on these boats are often still able to be wiped clean with about a tenth of the effort, while the rest of the hull becomes impossible to clean. Although I am still waiting for more real-world data from the new copper-only Pettit Trinidad and other hard paints, so far the same thing seems to be happening on various boats that received copper-only Pettit Trinidad from 2020 onward. The hull paint is failing after one year, while the areas that received 3 coats are still performing well, even with the weaker copper-only formulation.

23 foot sailboat, Richmond waterway. Boat and Boatyard not named because this is a paint failure case. See video.

Paint type: Micron CSC, applied February 2021

Bottom paint was applied on Feb. 9th 2021. Video was taken on Oct. 7th 2022. As the hull diver for this boat, I noticed the thin spots after a few months and I let the owner know. For many reasons it is difficult to bring a failed bottom paint back to the yard for warranty work. Frankly, it is rare to see anything resolved in these cases. The boatyard can easily deny anything is wrong with the paint, as they see it out of the water and they are judging it by its physical appearance, not its harder-to-judge antifouling properties. They can blame the paint company or other uncontrollable factors, ultimately taking no responsibility for the final results. For this 23 foot sailboat, I have the records of my correspondence with the owner on May 1st 2021, when the paint was only 3 months old. I cleaned the bottom while the owner was present. I explained the issues of missed spots and heavy fouling, and the owner showed me the boatyard invoice. The boatyard invoice states 2 coats of Micron CSC were applied. The invoice even contains an extra $1,050 charge for “additional underwater body preparation.” The moving of jackstands is actually spelled out in the “prepare and paint underwater body” section of the invoice ($1639.43). Total charge was $2999.46 for a 23 foot sailboat with no running gear, including the wintertime special and a 10% courtesy discount – this was not the bare minimum “haulout and paint” package.

The video shows the paint at 18-months old, with extensive areas of bare gel-coat where the paint was never anywhere near the manufacturer’s recommended dry film thickness. On a larger boat this poor workmanship would have made hull cleaning completely unmanageable. Technically, the paint was a total loss within about 9-12 months, but because it’s a small boat with no running gear, I was able to clean the bottom for a reasonable price longer than would be possible on a bigger sailboat. I cleaned the bottom every 2 to 3 months from April 2021 to October 2022, when the bottom was no longer possible to maintain. Many areas on this boat are still easily wiped clean using a light-duty 3m pad, the kind of material I use to clean race boats. What is the difference between the bare gelcoat spots, the now-heavily-fouled degraded spots, and the still-perfect-condition spots throughout the hull? The difference once again is the paint dry film thickness. This boat is a perfect example of the compromises that are too often accepted in this industry. The person who painted the boat was unqualified, to put it lightly. The boat owner might be too busy to take their boat back to the boatyard to get their paint fixed, or may not be knowledgeable enough to demand better results. The boatyard is also busy with an endless stream of customers, has a certain turnover of workers, and depending on the situation they may not have the resources to give every customer the VIP treatment. In the real world, many hull divers also overlook the unpainted areas until the owner’s eventual haulout reveals the diver was never cleaning the difficult bare gelcoat areas.

Improving the Chances for a Good Bottom Paint Job

The positive bottom paint jobs mentioned in the case studies have a few things in common that I think contributed to their success.

- Multiple coats of bottom paint. Again, the paint is only as strong as its thinnest spot. Even with two coats, how sure can you be that the paint film reaches a thickness of two coats everywhere on the hull? Is it possible that certain areas, even small valleys or pores in the paint invisible to the naked eye, have ended up with only one coat – or only half a coat? In the real world of boatyard projects, one coat of paint is as good as half a coat of paint. Applying 3+ coats of paint is an easy way to rule out this problem.

- Smooth texture. When the paint is smooth, it can be wiped clean in one wipe. If there are thousands of micro-valleys in the paint, these valleys are still filled with algae after one or two wipes, so the diver must go back and scrub deeper. This wears away the paint. Even after cleaning, the micro-valleys are still filled with trace amounts of algae, enabling the fouling to grow back faster and stronger than it would on a smoother surface. Imagine cleaning slime off a rough concrete floor vs. wiping slime from a polished concrete countertop: same material, different cleaning effort – simply due to the difference in texture.

- Multi-biocide paint. Irgarol-containing paint was the best, there is no debate. The next paint to emerge as the “best” paint will be another multi-biocide paint. At the moment limited products are available and I have only observed a couple of these multi-biocide paints in person:

- Seahawk BioCop TF. As far as I have seen, this is the most promising dual biocide paint. This “hard ablative” paint seems to perform exceptionally well at Richmond Yacht Club – the only location I have observed it so far. Soft coatings are especially prone to failure due to mechanical/structural wear and tear. I would recommend three to four coats of ablative bottom paint if multiple seasons of performance are expected in a high-fouling area.

- Pettit Black Widow. This paint works exceptionally well like any top-quality dual biocide paint. But, after seeing this paint over a couple of seasons, I think this paint is too soft for the real world.

- Pettit Odyssey Triton. I have not personally seen this new triple-biocide paint, but I would be very interested to try it next time I need a bottom paint job. In my opinion this checks all the boxes. But good bottom paint requires a balance of properties that work together to deliver the antifouling properties in just the right way. Not all paints have this magical balance of amazing properties, despite checking the right boxes. Still, I would not hesitate trying this paint, even without having seen anyone use it yet.

- Pettit Trinidad XSR – This is Pettit’s answer to the quest for a good multi-biocide paint. It contains the same chemistry as Seahawk Biocop TF. I have not personally seen this as it is not approved to be professionally applied in California, but it would be my top choice for a hard paint, based on the chemistry.

Common Issues with Bottom Paint Jobs

Boats often come back from their haulout with one or more of the following bottom paint issues:

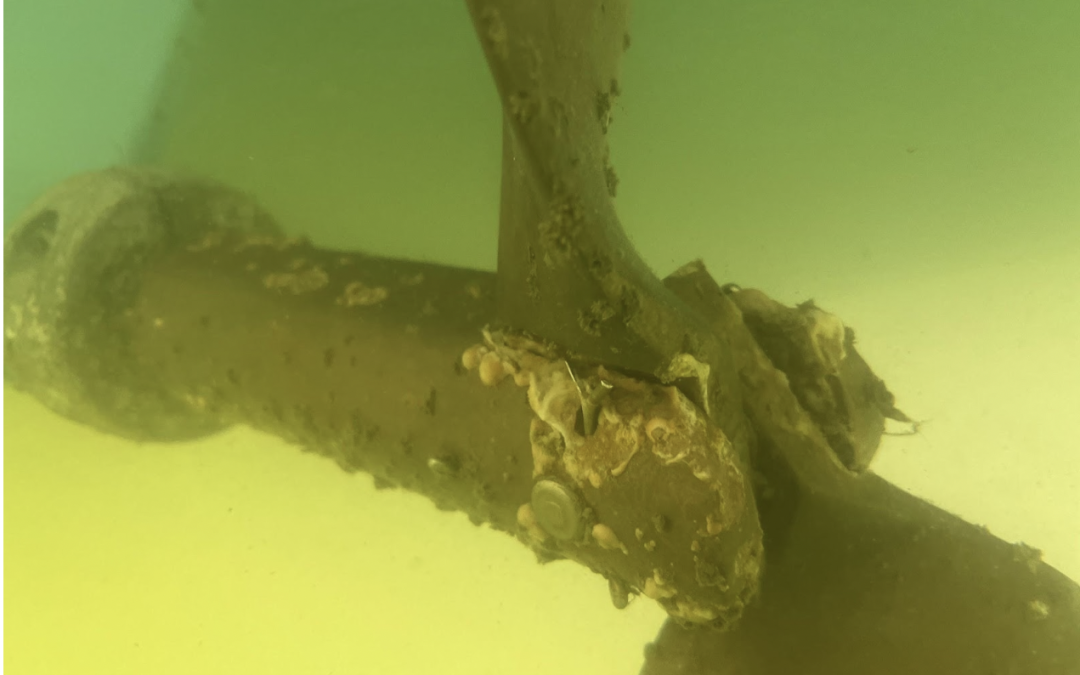

- Unpainted bottom of keel. See video of typical situation. This video is from a professionally applied paint job. In these cases the entire keel, or the keel block areas, are unpainted. This is an issue affecting at least 50% of bottom paint jobs. Even if the bottom of the keel is “painted,” often the keel is not sanded, primed or prepped as well as other easier-to-reach parts of the hull, resulting in the paint falling off the bottom of the keel after a few days in the water.

- Unpainted rudder bearing. The myth that plastic parts do not need bottom paint leads to this common mistake. An exposed, unpainted rudder bearing will become quickly fouled by the worst types of marine growth.

- Unpainted top edge of rudder. The unpainted gelcoat suffers from heavy fouling along the submerged portion of the top edge of the rudder. The rudder must be dropped or rotated, sanded and painted with 2+ coats of bottom paint.

- Thin paint edges on keel/rudder/chines. Anyone who has painted a boat, house or car has observed that corners are tricky to paint. Certain paints stretch as they dry. Generally paint seems to build up less easily at corners, leaving these areas with a thinner coat of paint. Almost every bottom paint job starts to fail at the corners and edges, which is not a big deal most of the time. But in some cases the wear and tear from these localized areas spreads quickly to the rest of the boat hull and reduces the longevity of the paint. Powerboats with multiple chines and right angles at the waterline and transom are the most affected by inconsistent paint thickness at the corners.

- Thin paint on jack stand square spots. See video of cleaning rough-textured AND under-applied bottom paint on jackstand spots. This is a 6 month old professionally applied bottom paint job. Note areas of thicker, smoother paint have no heavy growth, while areas of thin and rough-textured paint are affected by imbedded black algae. A common shortcut by the boatyard is to leave the jack stand spots unpainted until the boat is hanging in slings, ready to be splashed. The boatyard then has an hour or two to sand and paint the square jackstand areas. These areas receive a single coat of paint (sometimes even with a different brand or color of paint, whatever they happen to have at the time) just before splashing. I have seen hundreds of bottom paint jobs fail for this reason alone. For a high-quality bottom paint job, the jack stand spots must be treated exactly as the rest of the hull, not as an afterthought.

- Thin paint in various areas around the hull, “holidays.” You only see the evidence of thin paint once fouling has settled in more aggressively on these thin areas – at which point it is often too late to claim warranty. The reality of hand-painting is that the paint thickness will be inconsistent. This is one reason multiple coats are necessary. Rule of thumb: One coat of paint is as good as half a coat, two coats is one coat, and three coats is two coats. The thinnest paint spot will bring down the rest of the bottom paint job.

- Over-burnishing. If the paint is burnished down to a less-than-adequate paint film thickness, the paint will underperform and will need to be hauled and repainted within 12 months. This does not mean the paint performed well for 12 months; it means the paint was barely viable to begin with, was a nightmare to maintain for the final 6 months of the paint’s life, and was desperate for new paint in less than a year. The way to prevent this is to ensure that the final thickness of the dry paint equals two full coats, after burnishing.

- Rough-texture paint/orange-peel texture. A smooth surface is easier to wipe clean and stays clean longer. A rough texture is a haven for marine growth which roots into the paint. Roller-applied paint can be smooth. It must be applied at the right time of day with the appropriate roller and thinner. In the full sun or in windy conditions, the paint will not lay down smoothly before drying. If you find that the boatyard has given you a rolled paint job with the texture of non-skid or severe orange peel texture, it would be reasonable to demand a better finish. There are tried and true methods for getting smooth rolled paint, easily found in any of the bottom paint certification courses.

- Insufficiently sanded/prepped hull. If the old paint is chipping, it is necessary to sand away the old paint chips until the surface is smooth. If paint is applied over the old paint chips, the paint will be thin around the edges of the paint chips. Thin paint wears away prematurely, bringing down the entire bottom paint job.

- “Burn-back” or corrosion causing paint to “burn” and fall off around bonded through-hulls or other hardware. This is an issue to be addressed by a marine corrosion and/or electrical technician who can find the source of the problem before painting the bottom of the boat. New bottom paint is not a solution to burned bottom paint around hardware fittings. See ABYC Standard E-2.5.4 “Coatings 2.5.4.1. If antifouling coatings containing pigments that are galvanically incompatible with the substrate metal are used, then cathodic protection shall be maintained and a barrier coating shall be used between the antifouling coating and the substrate. NOTE: Prior to the application of a barrier coating on metallic surfaces, the surface should be tested for the presence of soluble salts. If salts are present on a surface, they should be reduced to an acceptable level of three micrograms per square centimeter prior to the application of a barrier coating. Special solutions for the reduction of soluble salts, as well as test kits, are commercially available. 2.5.4.2: Coatings on surfaces shall be capable of tolerating alkali generated by the cathodic protection system.”

- Paint flaking off metal hardware. Bronze and stainless hardware reject copper paint, due to galvanic corrosion between the paint and the substrate. Thru-hulls, rudder heel fittings, pintle/gudgeon hardware, and bronze stern bearings become a garden of seaweed soon after the boat is splashed, especially in cases where the hardware is electrically bonded together. Standard boatyards apply bottom paint directly over bronze hardware, so the owner must take initiative to see that these areas get prepped and treated for the best results. Bronze and stainless hardware should be wire wheeled and painted with epoxy primer or Propspeed before coating with bottom paint. Whenever you are replacing thru-hulls, do your future self a favor and apply epoxy barrier coat on the thru-hulls inside and out while it’s still clean and shiny. The same principle applies to external lead ballast and to metal keel fins. Coating with barrier coat also has the effect of prolonging the life of any zincs/anodes that are protecting this metal (see ABYC Standard E-2.5.3: “Immersed cathodic metal surfaces shall be favorably matched in anode to cathode area relationship. NOTE: Coating of cathodic metal surfaces may be used to achieve the relationship”).

- Paint that is too soft for its purpose. For example, on race boats with blade rudder and keel fin, white ablative paint is applied with the idea that the foils will benefit from self-polishing paint. However, ablative paint wears away faster than the hard bottom paint, depleting the bottom paint faster than it would otherwise. Soft paint should be applied with the understanding that it wears away quickly. Applying 3+ heavy coats of ablative paint can achieve long-lasting results, but unfortunately most applications of ablative paint (especially white color ablative) fail due to insufficient paint thickness.

- Incompatible paint system for the environment. Frequently, boatyards will apply a one-coat bottom paint job as a cheaper option. This works great if the boat is at a low-fouling location like brackish water or under a covered berth. If the boat is docked in a location exposed to fresh ocean currents and constant surge, or berthed at an end tie in any marina, the one-coat paint job will last about 12 months before it becomes impossible to scrub clean. The bottom line is, the paint job must be suited to the location and type of use. For demanding locations such as end ties or marinas near open water such as Pier 39 or San Francisco Marina, one coat of paint will barely last one year.

How to Assess a Bottom Paint Job for Long-Lasting Performance

- Look for 100% coverage on the hull and hardware, no exceptions. Keel block areas and jack stands should receive the exact same treatment as the rest of the hull. Bonus details: the transducer and outer plastic rim of knot meter fitting should be painted with antifouling transducer paint to keep these instruments functioning longer in between hull cleanings.

- Isolate metal hardware using epoxy primer or Propspeed. Any stationary metal hardware (trim tabs, stern bearing, prop strut, rudder heel fitting, bronze through-hulls, pintles + gudgeons, lead keel ballast) intended to be painted must first be painted with epoxy barrier coat or Propspeed. Copper-based bottom paint will rarely adhere to bronze or stainless hardware, especially if the hardware is bonded or has zinc protection. Additionally, Propspeed coating on propellers and prop shafts is highly recommended for all boats.

- Ensure a high-enough waterline. Make sure the entire underwater portion of the boat is painted with bottom paint. All too often, the boat sits below its painted waterline, resulting in heavy growth at the boot stripe. This growth at the boot stripe initiates a vicious cycle that spreads to below the waterline and ends up compromising larger areas of the bottom paint job.

- Check the paint texture. Rule of thumb: if the bottom paint has an orange-peel or non-skid type of texture, or looks like a bare concrete sidewalk with millions of small divots, the paint is not going to last long. The uneven surface invites heavier fouling and is harder to scrub clean. It will need more frequent and more aggressive scrubbing, and will need repainting approximately 1 year earlier than smooth paint, all other factors being equal. Solution: If the initial paint job ends up with a rough non-skid texture or orange peel texture, the recommendation is to burnish away the texture (removing as little paint as possible) and apply more paint using the proper tools and techniques.

- Inspect for a consistent paint film thickness equaling the manufacturer’s recommendations. There should be consistent paint film thickness throughout the entire bottom. Manufacturer’s recommendations from Pettit, Interlux, and Seahawk clearly state 2 coats, or “one coat per season.” However, the reality of hand-painting or hand-spraying is that the thinnest spots in the paint end up only equaling 1 coat or ½ coat thick. These spots, even if they start out as small, microscopic valleys or pores in the paint, will soon become the weakest link in the paint job, causing a cycle of paint wear and tear, ending in premature paint failure. We must account for human imperfection, so I advocate 3 coats for proper coverage on 100% of the hull, with 4 coats at the waterline and on the rudder – the high-wear and sunlight-affected areas. At least one boatyard has a different opinion, and this should be considered even if it contradicts the manufacturer’s recommendations. Linked here is KKMI’s article on bottom paint prep. Note the section about how applying one single coat of paint might actually be cheaper in the long run, since you will save money during your frequent haul-outs and you won’t run the risk of paint flaking off due to excessive thickness. The KKMI article claims that underneath the new paint, older coats of depleted bottom paint are somehow still providing antifouling protection. I encourage the reader to weigh the merits of these ideas and decide on an approach that works for you. Every owner must decide between a cheaper, short-term bottom paint job vs. a longer-lasting but more expensive bottom paint job. My position is firmly that it is better value and a better experience to do the long-lasting paint job. I don’t want to haul my boat every year, and I don’t want to see heavy marine growth after 12 months, even if I saved $1000 or more at the boatyard. My guess is that most owners, if they actually knew how bad their bottom paint is getting after one year with a single coat of paint, would also prefer a long-lasting paint job. Personally, I know many more boat owners who are unpleasantly surprised when their bottom paint dies after one year, than I know owners who are on their way to the boatyard for their yearly, affordable, quick and easy haul out.

- Remove all tape before splashing and check for any through-hulls plugged with tape or plastic or transducers covered in tape.

Other factors to Consider

- Impact of the boat location. Fresh water seems to be the lowest marine growth environment, as boats in the Sacramento River Delta do not suffer from barnacle, oyster, mussel, kelp or other seaweed growth. On the opposite side of the spectrum, cold ocean water seems to be the worst environment. Pier 39 for example, as a location for hull cleaning, has by far the most aggressive marine fouling anywhere in San Francisco Bay. Marine fouling occurs at Pier 39 at a rate of about 5 to 10 times faster than a marina in the Alameda estuary. In between these extremes there are microclimates inside each marina. The heaviest fouling in every marina happens at end ties along fairways, especially if the fairway is connected to open water rather than a protected channel. For example, a boat at an end tie exposed to the Alameda estuary has twice the growth of a boat just a few hundred feet further inshore, even on the same dock. Even the outboard-facing side of the hull will have much heavier growth than the dock-facing side of the hull, especially on an end tie. The current, sunlight and fresh ocean nutrients flowing under the hull invite heavier fouling. For example, some boats at the Brickyard Cove neighborhood in Pt. Richmond benefit from an astonishingly low rate of fouling and can easily go 6 months between cleanings. However, in other areas of this neighborhood where current rips faster, the fouling is much heavier and the boats need to be cleaned monthly to get the same results.

- Paint quality. Among dozens of choices, there are some clear best and worst choices most hull divers and boatyards pretty much agree on. Some surprising exceptions such as West Marine’s low-cost house brand paint have proven surprisingly effective. Boatyards have their preferred paints and methods for a good reason; it is time-consuming to learn the specifics of each paint system. Experimenting with lesser-known paint has a high failure rate. It is a choice between going with whatever is best known and available in the local area, vs. experimenting with new paint that may not give the desired result.

- Quality of Labor. Arguably the biggest factor in long-term paint performance is the prep work and application technique/methods. Does the boatyard have a painter who knows this paint system? How are they training new recruits? Will they stay organized throughout the entire multi-step process of painting the bottom, or will certain steps get rushed or entirely overlooked? Is there any accountability if, for example, you pay for extra sanding of chipped areas and then you find out later that sanding work was done poorly? What if you pay to have the external lead ballast refinished at a cost of several thousand dollars, only to discover that the keel block areas were not refinished and still have bare lead exposed to water? These are real-life examples not to undermine boatyards, but to convey how difficult and time-consuming it really is to achieve spectacular results even in a professional boatyard. Exceptional results really are the exception. If you want the best work done on your boat, it takes knowledge, dedication to the project, and highly skilled labor.

In Conclusion

I believe the above ideas can be effective despite the paint not being as powerful nowadays. If it were my boat (it eventually will be when I need to repaint with the new generation of paint), I would apply 3 coats on the hull, 4 coats at the waterline and rudder, and would expect no more than 2.5 years of good performance. I might add a coat or two of multi-biocide ablative paint over the hard paint to boost performance for the first 1-2 years, with the expectation of losing the ablative paint over a period of time. Experimentation within the bounds of the manufacturer’s recommendations would be my approach.

For more information about the idea of applying soft ablative paint over hard bottom paint, see this downloadable slideshow from Seahawk Bottom Paint’s “Certified Applicator Training Session” in which a boat bottom is painted from the fiberglass up. Barrier coat is applied, followed by one “signal” coat of hard (Seahawk Talon) bottom paint, then 2 coats of soft ablative (Seahawk Biocop TF) bottom paint – totaling 3 coats of bottom paint.

Miscellaneous Paint-related Products

- Propspeed: Now becoming a necessity at least for the summer season in San Francisco Bay. One month of growth on bare metal in summertime can cause a folding/feathering prop to be inoperable in some cases. For larger power boats, the cost of Propspeed pays for itself in fuel savings. Propspeed cannot be applied over previously corroded propellers– it will flake off. The prep work must be meticulous. The yellow primer must be heavily applied, otherwise the silicon topcoat will peel away. Under-applying the yellow primer is a common cause for Propspeed failure. A good Propspeed application can last 3 or more years even in high-fouling areas.

- Gray Spray Coating on metals: Gray spray coating under the name “Barnacle Barrier” or similar. These products are not worth the trouble, in my opinion. The performance is so weak that it’s hard for me to tell if it really does anything at all. Even at their best, gray spray coatings might reduce propeller fouling by about 25%, and only then for about 6 months before they lose effectiveness. If someone is selling you a $40 can of gray spray paint as an equivalent to a $400 Propspeed kit, remember you get what you pay for.

- Environmentally-friendly Paint: Unfortunately, I have not yet seen an effective eco-friendly paint in San Francisco Bay. These paints have a 100% failure rate on the 10 to 15 examples I have seen. Failure means the hull is fouled beyond a diver’s ability to clean the hull by hand in the water. The hull becomes severely choked with grass and/or barnacle growth, and the owner is left with an expensive mess.

- Coppercoat: I have observed about 10 boats coated in Coppercoat epoxy coating. After 6 to 12 months in the water, I have had to give up each of these boats due to excessively stubborn fouling that was impossible to scrub clean. I no longer accept hull cleaning jobs on Coppercoat due to the difficulty of removing grass and algae from this product.

Recommended Bottom Paints: I have found just a few types of paint that stand up to SF Bay’s marine growth. When applied well, these paints have given excellent performance for up to 3.5 years (assuming a top-quality paint job and regular hull cleanings are performed):

- Seahawk Biocop TF. More durable than Micron 66, Micron CSC, Pettit Vivid + other ablative paints. Seahawk’s newer generation of Biocop “hard-ablative” multi-biocide paint has proven itself to be long-lasting and high-performing. It seems to be the best all-around solution for the average racer/cruiser type of boat. (NOTE: One clue that Biocop TF is working well is that the competitor Pettit came out with their own new “Trinidad XSR” model of their traditional “Trinidad” paint, clearly in response to the need for multiple biocides. The new Trinidad XSR formula contains the exact same triple-biocide profile of three biocides as Biocop TF. I expect Trinidad XSR to become the best-performing hard bottom paint, but have not observed it as it is not yet approved for commercial use in California as of March 2023. DIY painters can order it and apply it themselves in California.)

- Pettit Trinidad SR, Interlux Ultra, or Z-Spar The Protector containing irgarol. This was hands-down the ultimate bottom paint. If you can obtain new-old-stock of this paint, it is highly recommended.

- Interlux Micron 66 – soft ablative paint does need to be applied by a knowledgeable tradesman, but this paint performs exceptionally well in high-fouling locations. 3 coats are recommended.

Not-Recommended Bottom Paints:

The following bottom paints have been found to provide insufficient antifouling protection on many examples of San Francisco Bay Area boats. Keep in mind: these examples are based on a limited sample size, some of which were gleaned from conversations with other marine technicians and boatyards. You or your boatyard might be able to get better results from these products, depending on your knowledge of the product and the use case:

- E-Paint – Many cases of adhesion issues. In the cases I have seen, the E-Paint gets fouled by grass and black “mold.” Very difficult to clean.

- Coppercoat – single biocide (copper) does not prevent grass or embedded black “mold” algae in San Francisco Bay. Based on a sample size of 10-15 boats, this product seems to work great for about 6 months and then starts to allow grass and black “mold” to grow, especially along the waterline. Very difficult to scrub clean. I do not accept jobs on Coppercoat-painted vessels because it is too hard to clean these boats.

- Interlux Baltoplate – not recommended because this paint needs to be cleaned weekly in order to stay ahead of marine growth attaching to the paint and damaging it. Extremely difficult to clean if neglected for longer than 7 days, especially if the Baltoplate is older than 6 months old. Boats from Seattle berthed in SF Bay or Los Angeles for Transpac should be advised they need to clean the bottom daily or weekly to avoid stubborn marine growth on the hull.

- SeaHawk Tropikote – does not perform long-term, despite the impressive copper content in this paint. Single biocide paints generally underperform even if they have high copper content.

- SeaHawk Sharkskin- low copper content, single biocide.

- Pettit Vivid – Too soft for real world use. Wears away quickly when cleaned regularly by a diver. Could be a great paint, but requires a knowledgeable applier. Difficult to get consistent results with this product.

- Pettit Hydrocoat – offers no antifouling protection against seagrass. This paint does not hold up to marine growth in SF Bay. For aluminum boats, use a different non-copper multi-biocidal paint in place of Hydrocoat.

- Pettit Trinidad (new generation of single-biocide copper-only Trinidad) – Many applications of this paint suffer from grass at the waterline within 6-12 months. Very difficult to get good results even with professional application. Single biocide does not seem to provide antifouling protection from our multiple marine fouling species in SF Bay.

Additional links and resources

- The Complete Guide to Antifouling Paint – A UK-based guide contains good food for thought.

- https://www.practical-sailor.com/boat-maintenance/a-fast-bottom-paint-finish – Excellent study of paint prep and rolled application.

- https://www.kkmi.com/wp-content/uploads/2017/02/KKMI_Bottom_Painting.pdf – An overview of KKMI’s methods. Interestingly, I disagree with their theory in the “One Coat or Two” section. I encourage you to take something from each side and go forward with both perspectives in mind.

- https://www.seahawkpaints.com/wp-content/uploads/2015/03/2013-Portland-Yacht-Services-Training.ppsx – Downloadable PDF slideshow. Seahawk Bottom Paint “Certified Applicator Training Session” Slideshow showing 3 coats of bottom paint applied over barrier coat. Contains good details about paint texture and paint roller methods.

- Bottom Paint Calculator – Helpful starting point to compare real-world results with pre-calculated paint quantities. For example, if I intend to apply three coats of paint, how much do I end up using compared to what the calculator suggests?

- Bottom Paint Cross Reference Guide

- https://web.archive.org/web/20170801030116/http://www.kkmi.com/irgarol-is-back/ – Web Archive of KKMI’s letter to customers in 2017 announcing irgarol was available after a supply chain disruption. Contains some info about irgarol.

- https://www.practical-sailor.com/boat-maintenance/paints/bottom-paint-test-report-panels-rated-at-the-one-and-two-year-marks – Practical Sailor in-depth bottom paint tests.

- https://pettitpaint.com/media/4777/pettit-paint_antifouling-compatibility-chart_technical-bulletin.pdf – Bottom Paint Compatibility Guide

- https://pettitpaint.com/media/3079/vivid-xl-pds-2016-1.pdf – Pettit Vivid “User Manual.” Note the specification for recommended paint coats: “Number of Coats: 1 minimum per season with additional coats for extended service.”

- https://www.pettitpaint.com/media/4345/performance-antifouling-spray-and-burnishing-guide.pdf – Pettit Vivid/Black Widow “Spray Application Guide.” Note the specification for recommended paint coats: “Apply three THIN coats allowing product to cure between coats, apply a fourth coat if burnishing is planned. Coats MUST be sprayed on thin (4 mil max).”

- https://www.bottompaintstore.com/images/File/Pettit/Trinidad-SR.pdf – Old Formula Pettit Trinidad SR Technical Information

- https://www.yumpu.com/en/document/read/39271450/trinidad-pro-product-data-sheet-pettit-marine-paint – Old Formula (irgarol) Pettit Trinidad Pro Technical Information

- https://www.pettitpaint.com/media/4018/pettit-trinidad-antifouling-bottom-paint-pds-17.pdf – New Formula Pettit Trinidad Technical Information

- https://www.seahawkpaints.com/wp-content/uploads/2019/04/TDS-BIOCOP-TF-4-16-19-w-metrics.pdf Seahawk Biocop TF Manufacturer’s Recommendations: Typical Film Thickness: Pleasure craft: 3.0 mils (76.2 µ) dry film thickness(DFT) per coat, (5.3 mils (134.62 µ) wet film thickness(WFT)), 2 coats on entire hull and a 3rd at the waterline and other high wear areas.

- https://sisupainting.com/two-coats-better/ – a look at why “two coats are better than one” for house painting. The same principles apply to painting the bottom of a boat.

- https://kiwiprop.us/antifouling.html – Helpful tips on applying Propspeed or other antifouling to propellers.

Ask Lowell

More Articles

Anode Issues

Anode Fasteners Falling Out Anodes lose material...

How to properly install anodes

If you are tired of replacing your anodes every...

Zinc anodes are not protecting the propeller

Have you ever had an anode just not seem to be...

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220