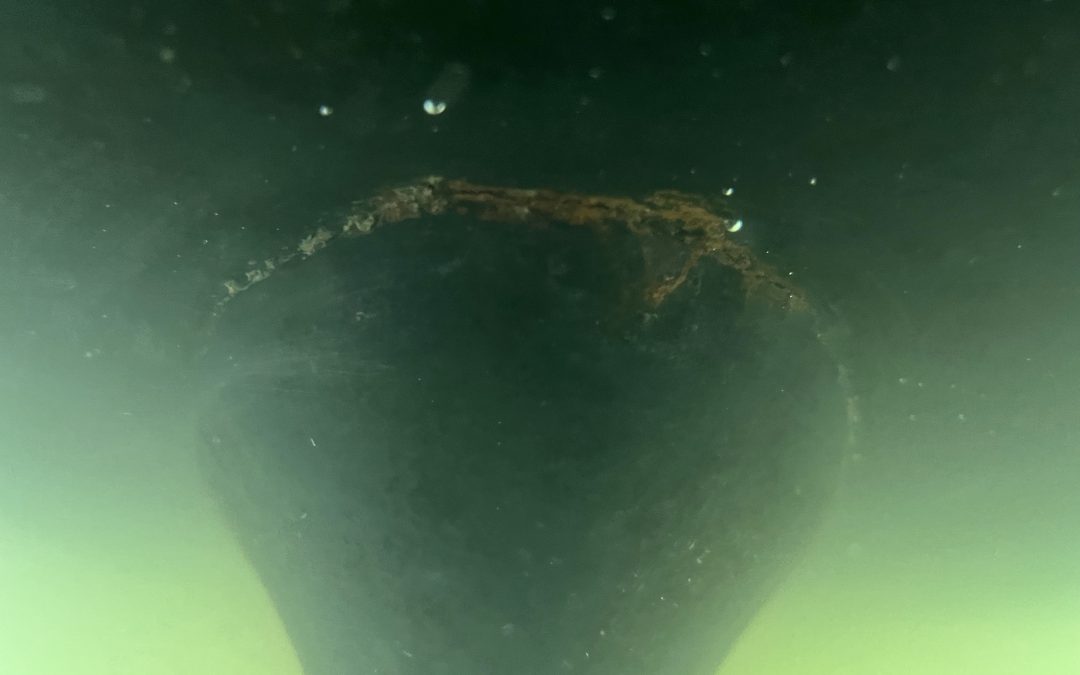

Whenever a propeller has previously suffered from pink metal or pitting, it needs special prep work to reapply Propspeed. Wire wheeling is not enough, as shown on this Autoprop, which received a professional Propspeed application only four months before these pictures were taken.

The professionals did everything correctly; wire-wheeling the entire propeller, following the procedure for Propspeed application, but this did not ensure the Propspeed would adhere to the previously pink metal.

Bronze is an alloy of copper, tin and other metals like nickel or aluminum. When the bronze shows corrosion, this means that certain metals are no longer present at the surface, while copper usually becomes the dominant metal at the surface. Oxidized copper is not an ideal surface to paint, so there needs to be a process of exposing the correct alloy again. This might be achieved by acid etching, electroplating, or another process of restoring a stable alloy to the surface.

Grinding or wire-wheeling could potentially eliminate the problem, but so far I have seen too many Propspeed failures in this category that I’m not optimistic about simply wire-wheeling or grinding.

“Photo shows a brand new Propspeed application that is flaking off the propeller. Failures of Propspeed are extremely rare, but when you’re dealing with a previously corroded propeller, Propspeed will usually not stick.”

Keywords: propspeed, propeller prep work, pink metal, pitting, corrosion, bronze, copper, tin, nickel, aluminum, acid etching, electroplating, stable alloy, wire-wheeling, grinding, propspeed failures

Related Articles

Bottom Paint Guide

In 10 years of tracking bottom paint performance, I’ve noticed a variety of results – good and bad – in the performance of bottom paint.

Anode Issues

Anode Fasteners Falling Out Anodes lose material...

How to properly install anodes

If you are tired of replacing your anodes every...

Rusting Keel Fins

Beneteau keel fins (a very common brand of...

Is my boat in a hot harbor?

The problem of "hot harbors:" There are marinas...

Red Tide/Algae Bloom

During August & September 2022, San...

Ask Lowell

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220