The problem of “hot harbors:” There are marinas or harbors where stray electrical current is blamed for corrosion on a boat’s metal components. This stray electrical current can come from a variety of sources, such as faulty marina wiring, or nearby boats with faulty electrical wiring.

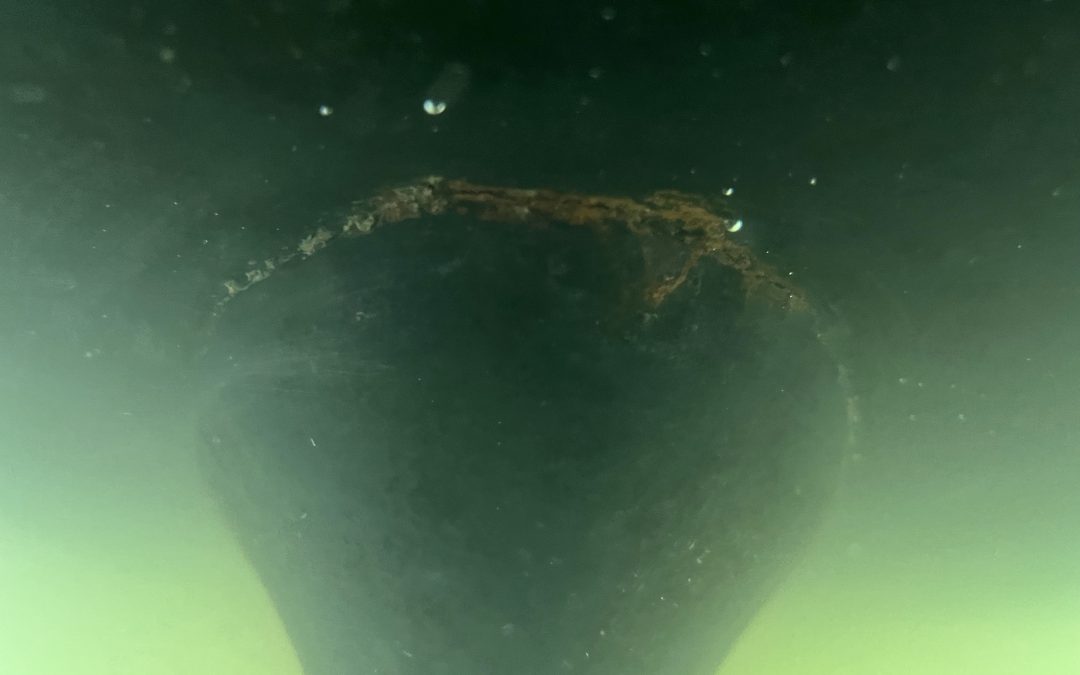

Fortunately, these situations are less common than most people fear. 99% of the time, galvanic corrosion is to blame. Actual stray current corrosion is fast, agressive, and pretty uncommon – think Sterndrives dissappearing in a matter of weeks, or thru-hulls turning to swiss cheese in a matter of hours.

Before suspecting stray current corrosion, always perform a thorough inspection of the ground paths of all electrical circuits on a boat, and measure the galvanic potential between the internal engine ground to the outside water.

To quickly inspect and rule out internal problems without going through the trouble of doing a comprehensive corrosion inspection, I would recommend the following action steps:

1. Install a galvanic isolator: Any boat with a permanently installed onboard AC system should have a galvanic isolator? Why? It’s the #1 way to rule out corrosion between a boat and the outside environment. It works like an electrical check-valve in the green AC grounding wire, allowing current to pass into the boat but not out of the boat, effectively isolating the boat’s electrical system from the marina’s and other boats’ electrical systems. Simply installing a galvanic isolator can vastly improve the onboard corrosion activity on a boat.

2. Going a level deeper, check and maintain the DC wiring, bonding wires, and green AC grounding wire, making sure there is no DC current flowing through the green bonding wires by testing with a multimeter and switching each DC load one by one. At the same time, make sure there are no DC wires hanging in the bilge and no closed circuits on improperly wired bilge pumps. Ensuring that the boat’s DC and grounding wiring is in good working order is essential for protecting against corrosion and electrical hazards. This includes any lightning grounds, CATV cables, and RF ground planes. A thorough inspection can detect and find the source of 12V or 120V ground faults on the boat.

3. Isolate underwater metals: If the metal is completely coated by something like epoxy barrier coat, there is no way the metal can corrode. Issues with corrosion, even dangerous stray current corrosion, are simply not an issue unless the metal is exposed to an electrolyte such as seawater or bilge water.

4. Monitor and test regularly: Regularly monitoring and testing the boat’s electrical system can help to identify and fix any problems before they become serious. This includes testing the galvanic isolator and grounding system to ensure that they are functioning properly.

By following these steps, boat owners can ensure the onboard electrical system is isolated from the effects of possible “hot harbors” and ensure the safety and reliability of their electrical systems.

Keywords: hot harbors, marinas, harbors, stray electrical current, corrosion, metal component, boat damage, safety hazards, ungrounded electrical systems, faulty marina wiring, industrial operations, electrolysis, galvanic corrosion, internal systems, electrical circuits, potential, galvanic isolator, direct current, alternating current, grounding system, corrosion-resistant materials, stainless steel, bronze, isolation transformer, stray voltage, shore power filter, boat electrical system, vessel protection

Related Articles

Bottom Paint Guide

In 10 years of tracking bottom paint performance, I’ve noticed a variety of results – good and bad – in the performance of bottom paint.

Anode Issues

Anode Fasteners Falling Out Anodes lose material...

How to properly install anodes

If you are tired of replacing your anodes every...

Rusting Keel Fins

Beneteau keel fins (a very common brand of...

Propspeed not sticking to previously corroded metals

Whenever a propeller has previously suffered...

Red Tide/Algae Bloom

During August & September 2022, San...

Ask Lowell

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220