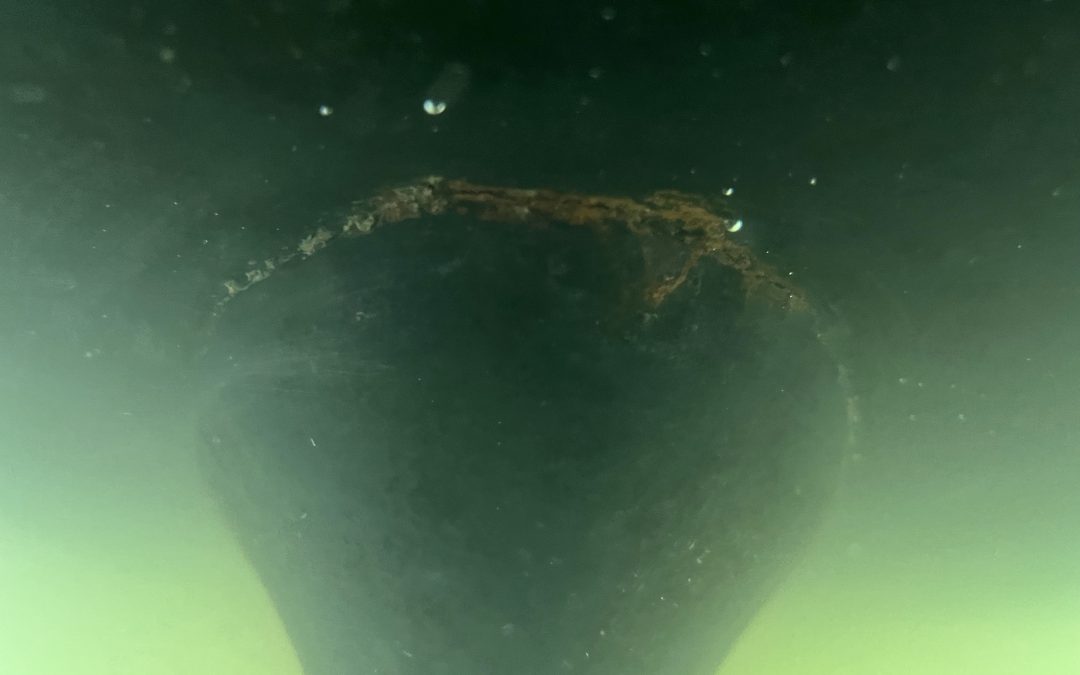

First, what exactly is “bottom paint haloing?” It’s when the antifouling paint on the bottom starts to blister and lose its antifouling effectiveness, usually in a circular pattern around submerged metals like thru-hulls, struts, or rudder posts. Many other names such as “burn-back” can apply to this phenomenon. The internet is full of mystified boaters debating the causes and solutions to paint haloing. Fortunately, the experts at the ABYC have an authoritative depth of knowledge on this topic. This article is based on the ABYC’s teachings.

Haloing is common on bonded hardware, as the bonding system can introduce a greater galvanic potential (i.e., lower voltage) than would be produced by the innate properties of the metal alone. For example, an isolated piece of silicon bronze hardware will likely not suffer from paint haloing. The classic example is a plate zinc near the stern of a boat, with a bonding wire connected to the rudder fittings or bronze stern bearing, and a corresponding heavy garden of seaweed growing from the damaged paint.

Haloing is NOT corrosion, as there is no damage to the underlying metal. It is related to the phenomenon of “over-protecting” a boat, but at a vastly lower level. Strictly, haloing damage is caused by the flow of excess galvanic current from a cathode (in this case, the underwater metal in question) into the water, producing sodium hydroxide – an alkaline substance also known as lye – that “burns” the bottom paint.

What it is:

– Sodium hydroxide damage to antifouling paint, caused by electrochemical activity originating in the boat’s internal cathodic protection system.

What it is NOT:

– Corrosion of the underlying metal.

– “Electrolysis”

– A normal, inevitable consequence of painting submerged metal.

So, how can you prevent haloing? One option is to perform a corrosion survey on the entire boat. You would be looking at potentially rewiring and reconfiguring the anodes and/or the bonding system on the boat. You could try removing an anode or using a smaller size of anode. This is a process to be performed carefully by an experienced corrosion technician.

The easier, cheaper and more fool-proof method you might want to consider, is coating the underwater metal with an epoxy barrier coat. This will isolate and prevent the metal from interacting excessively with the water. If your boat has multiple points of haloing at every thru-hull or bronze fitting, it might be faster and cheaper to simply replace the thru-hulls with non-conductive Marelon, or install new thru-hulls that you have completely coated in epoxy barrier coat. If you want to try this out without the commitment of replacing fittings, try simply refinishing the outside surface of the hardware using epoxy barrier coat on and around the metal. Remember: any exposed metal will likely cause haloing and heavy marine fouling to some extent, including inside your thru-hulls.

Haloing can not be fixed by simply sanding away the damaged paint and repainting the affected areas with antifouling paint. The metal will be wet and thus will produce excess galvanic current, and the paint damage will come back until the underlying cause is resolved.

We offer consultation to our clients on how to address bottom paint haloing and other underwater issues. Whether it’s installing new cathodic protection systems, reconfiguring the bonding system, or coating the metals with epoxy barrier coat, we’re here to help you find the solution that works best for your boat.

Keywords: boat maintenance, bottom paint burnback, underwater metal protection, paint peeling, paint blistering, propeller, poor bonding system, electrical current, stray current, water damage, electrical isolators, bonding system reconfiguration, epoxy primer, corrosion prevention, boat consulting, underwater issues, electrical issues, boat repair, boat performance, boat shape, boat protection

Related Articles

Bottom Paint Guide

In 10 years of tracking bottom paint performance, I’ve noticed a variety of results – good and bad – in the performance of bottom paint.

Anode Issues

Anode Fasteners Falling Out Anodes lose material...

How to properly install anodes

If you are tired of replacing your anodes every...

Rusting Keel Fins

Beneteau keel fins (a very common brand of...

Propspeed not sticking to previously corroded metals

Whenever a propeller has previously suffered...

Is my boat in a hot harbor?

The problem of "hot harbors:" There are marinas...

Ask Lowell

LH Marine serves all marinas and homes in the SF Bay Area.

Phone: (510) 470 – 9220